Grinding and Dispersion Technologies

Grinding/Dispersing/Mixing

SiLiBeads® ...Better Grinding

Grinding media in all its variety is our expertise. We have been producing high-quality glass beads and ceramic beads for more than 160 years.

Our quality management to DIN ISO 9001 has been approved for years.

Quality and Know-how

Each production batch runs through a detailed quality check for diameter, sphericity, wear behaviour, inner structure and specific weight. We have established ourselves as specialists with our great accumulated experience and know-how in the field of grinding technology.

Besides the manufacture and distribution of grinding media, we also deal intensively with wet grinding technology.

We even work with attritor mills/pearl mills in our ceramic bead production and seminars, and can therefore offer our customers practical advice and optimize customers’ production processes by suitable measures.

Service

In addition, we offer reprocessing and follow-up work for used grinding media. Our customers obtain cost-cuttings in beads consumption through this.

We stand for high quality of our products and for an effective use of our grinding media in order to obtain the highest customer benefit and provide customers with the best value.

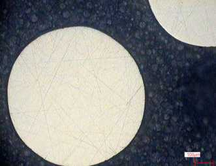

Zirconia/Yttria, competitor Asien

Zirconia/Yttria, SiLi Type ZY-P

The best size of grinding media depends on the particle size of the milling product at the BEGINING of the milling process and the desired particle size at the END of the milling process.

It is to distinguish between:

- Real crushing process and a deagglomeration process

- Easy to grind products: Smaller grinding media can be used

- Difficult to grind products: Larger grinding media are more effective

- The grinding media should be 2 – 3 x larger than the separator or mill filter (slotted pipe or gap, screen cartridge).

- The grinding media should be at least 5 x smaller than the distance between the stirrer disc and the wall of the mill chamber.

- The grinding media should be about 20 to 30 times larger than the particle size of the milling product at the beginning of the milling process (d95).

- Feasible average particle size ( d50) of the milling product is about 1/1000 x of the grinding media. Example: bead size 2 mm → d50 = 0,002 mm = 2 µm.

Get In Touch!

Mumbai

Grinding and Dispersion Technologies

Office No. 3,Sree Sai Ram Co-operative Housing Society,

Near Ram Mandir Railway Station, Ram Mandir Station Road, Goregoan West-400104

Goa

Grinding and Dispersion Technologies

House No. B1, Besides Betim Panchayat Office,

Opposite Betim Ferry Wharf, Betim,

Bardez, Goa- 403101